What Materials is Used to Make Stickers At Home 2023

Stickers are the most familiar word for all age groups belonging to any field or profession. Most people think stickers are just used for decoration purposes only. Stickers are becoming part of journaling essentials nowadays as designing journals becomes a leisure time activity for girls especially.

Custom stickers are a great way to add personality to your belongings or to show support for a cause or organization. You can also use them as gifts, or to promote your business or blog. If you’re looking for a unique and fun way to express yourself, making custom stickers is the perfect solution!

Moreover, Those who are thinking of giving a start kick for their small business or startups also use stickers for advertisement purposes and most of them design logos print them on stickers and adhere them to their products.

But the question arises here what materials is used to make stickers at home?

So, let’s take a glimpse at it.

What Materials is Used to Make Stickers

Materials used for Making Stickers

Nowadays stickers are used as the best tool for marketing and branding. but wait…before employing it you have a brief knowledge about materials types and which material is suitable for what kind of product. Each material has some advantages and disadvantages as well, therefore, gives accommodation.

The packaging available in the market is:

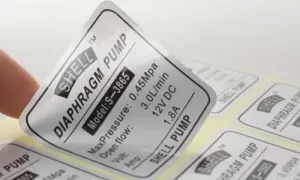

1.Paper Stickers

Due to their versatility and for being very economical and writable paper stickers are used widely for indoor purposes like box labeling labels on food boxes, invitation cards, and much more alike.

But the major drawback is its single use, being not waterproof and tearproof.

Paper stickers are marketed as:

- Glossy Mirrorkote Paper Sticker

- Woodfree Paper Sticker

- Kraft Paper Sticker

2. Synthetic Stickers

These are dampproof, tearproof, and pliable. Yes, you are thinking right. These are mostly used in bottles, and cosmetic packages because of their good adhering power to stick on curved surfaces but this property makes them more expensive than paper stickers.

These are available in the market as:

- Matt synthetic stickers

- Holographic stickers

- Clear stickers

- Foil stickers

Foil stickers

3.Vinyl Stickers

If you are in search of labeling outdoors then vinyl stickers are the best options. The characteristics like water-resistant, tearproof, durable, and recyclable make them more costly than others. Used as: Bumper stickers, window stickers, phone laptops, and machinery.

Available in the market as

- Standard vinyl stickers

2.Clear vinyl stickers

4.Waterproof Stickers

With the advancement in technology, everything goes through an upgradation process and thus stickers do too. Waterproof and water-resistant stickers are one of them. But most people consider waterproof and water-resistant as the same thing but they are slightly different from one another. Let’s discuss the main difference between the two:

Waterproof stickers can be applied everywhere except the bottom of a submarine and the surface with leaks and cracks while water-resistant are made of polypropylene material and can’t be applied to oily or dirty surfaces so make sure to clean and dry the surface before applying.

Some other Materials Available in the Market

- Polyester

It is popular for its metalized look which gives a mirror-like shine and is mostly applied to pipes and panels as it can bear oppressive conditions.

- Recycled

The name already clearly defines the type of material itself. it is made of 100% biodegradable stuff. However, they are not oil and water-resistant.

- Satin

These are made up of a special type of fabric material called satin acetate that’s why named satin and mainly used for wine packaging.

- Fluorescent

As the name clearly describes the nature of the material. It is a very shiny material available in various hues like red, orange, pink, and green. Mainly used for alerting people.

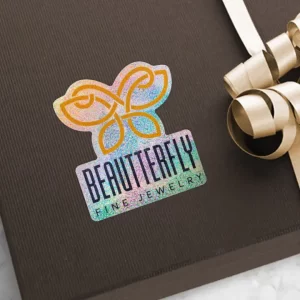

- Holographic

Have you ever seen a car with a glowing material on its mirror or at the back?

Yes, that is called holographic material, made of metalized vinyl paired with permanent acrylic adhesive. the highly deliberate metallization coating provides a magnificent outcome even in dark or dim environments.

- Glitter

Who doesn’t like glitter, everyone loves the shine. if you are wandering to add a blaze these are the best way to bring up an illusion in your life.

The Best Material in the Market

There is a vast range of materials to choose from but which material best meets your demand is of main concern. Although the Selection of the best material for the manufacturing of stickers is one of the most devastating confrontations.

Let’s have a look at the finest material of all.

- White Vinyl, the type of vinyl sticker is the most reliable and durable material for outdoor purposes of all because it is UV resistant and waterproof and lasts up to 5 more years

- One other best material is BOPP (biaxially-oriented polypropylene), an oil and water-resistant material.

Costing

When it comes to cost, it does not only mean a piece of adhesive material but it’s a matter of color, quantity, method of printing, type of material, and size that affect the cost of sticker material and printers. Personalized stickers are on its trending nowadays in the market and every manufacturer is knowledgeable about the critical factors that may cause fluctuation in the final product pricing.

- The cost of adhesive vinyl sticker roll ranges between $58.00 – $68.00. You can find vinyl stickers at the most reasonable prices at Alibaba.com.

- While the role of synthetic stickers costs about $0.01-$0.60 / piece.

Which Material will be Best for You?

Net surfing is the easiest way to find your way that what material would be compatible with your small startup, logo making, or any other case. A diverse group of sticker veterans claims their product is the world-class quality but wait this is the marketing strategy, no need to change your mind with all that stuff. Just focus on your case.

If you are looking for an eye-catching reliable and water-resistant sticker then this sounds like a vinyl sticker.

If you are looking for viable and biodegradable material then go for brown craft paper stickers.

The Most Durable One

The most censorious part of any business is the durability of the product that have be sold by the vendor because it’s all about the customer’s perception of buying the right product according to their need.

As already discussed above vinyl stickers are considered the most durable as the stickers bear up against chafing and extreme weather conditions, another layer of vinyl makes them waterproof and last longer.

But vinyl stickers are prone to cancer due to the presence of phthalates compound which is very harmful to human health that’s why these sticker materials are not regarded as GRAS (generally recognized as safe) and couldn’t use for food, beverages, and cosmetics.

Synthetic stickers are the best alternatives for vinyl stickers as they also can bear up against mechanical stresses, humidity, and mild weather fluctuations

Printer and Sticker Paper

The type of printer you use will determine what kind of sticker paper you can use. For this project, you’ll need either a laser printer or an inkjet printer. If you have a laser printer, you can use any type of sticker paper. However, if you have an inkjet printer, make sure to use sticker paper that is specifically designed for inkjet printers. You can find this type of sticker paper at most office supply stores, or online. The popular sticker papers are of many types like white, clear, glossy, and matte. You can also find pre-cut sticker sheets that are easy to use.

Cost of Sticker Printer Ranges $100 to $1000

Glossy Sticker Paper Cost $15 to $25

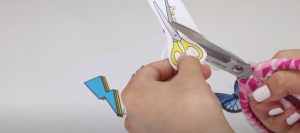

Scissors or Cutting Knife

Next, you’ll need a sharp pair of scissors or a cutting knife to cut out your stickers. If you’re using a cutting knife, be sure to protect your work surface with a cutting mat.

Scissor Cost $5 to $10

Adhesive Vinyl (Optional)

If you want to make stickers that are waterproof and durable, you can use adhesive vinyl. Adhesive vinyl is a type of plastic that comes in sheets, and it’s very easy to cut out with a cutting knife or scissors. Adhesive vinyl is also available in a wide variety of colors, so you can find the perfect shade to match your project. You can purchase adhesive vinyl at most craft stores, or online.

Clear Contact Paper (Optional)

Clear contact paper is a type of plastic that comes in rolls, and it’s very easy to cut out with a cutting knife or scissors hence delivering the glossy or matte finish to your stickers. Clear contact paper is also available in a wide variety of colors and finishes, so you can find the perfect match for your project. You can purchase clear contact paper at most office supply stores, or online.

A Computer and Internet Access

You’ll need a computer and internet access to design your stickers. If you’re not sure what design you want, you can search the internet for inspiration. Once you’ve found a design you like, you can use a graphics program like Adobe Photoshop or GIMP to create your own custom version.

Design

After finding the design, open the program, and start by creating a new file that is the same size as your sticker paper. Then, using the shapes tool, create a rectangle that is the same size as your sticker. Next, add your design to the rectangle. You can do this by importing an image or using the paintbrush tool. Once you’re happy with your design, save the file and print it out on your sticker paper. Many printers have also apps wherein there are a lot of designs, and you can directly print them from there.

After your design is printed, carefully cut out each sticker with scissors or a cutting knife. If you’re using adhesive vinyl, weed out the parts of your design that you don’t want to be sticky. To do this, use a weeding tool to remove the vinyl around your design.

Now your stickers are ready to use! You can stick them on notebooks, laptops, water bottles, or anywhere else you can think of. Show off your creative side by making custom stickers for yourself or for your friends. With a little time and effort, you can easily make unique stickers at home using everyday materials.

Sticker Printing and Die Cutting

There are a few ways to make custom stickers at home. The most popular way is to use a die-cutting machine, but you can also print them yourself using sticker paper.

To make die-cut stickers, you’ll need a cutting machine like the Cricut Explore Air 2, Silhouette Cameo, or Silhouette Portrait 3. You’ll also need cutting mats, transfer tape, and vinyl or paper. For printed stickers, you’ll just need sticker paper and an inkjet printer.

If you want to make die-cut stickers, start by designing your sticker in the software that came with your cutting machine. Then, load your vinyl or paper onto the cutting mat and feed it into the machine. The cutting machine will do the rest of the work for you! To make printed stickers, simply print your design onto sticker paper and cut them out with scissors.

Die-cutting Machines Cost $50 to $700

Conclusion

Making custom stickers at home is a great way. With the right materials and a little bit of know-how, you can make custom stickers that are perfect for any occasion or your personal use.

Granting all this, a huge variety of stickers are available in the market to take into your attention when you are all here to choose or create stickers for your small business or make a logo for your product, or gift it to your loved ones.

If you belong to a candle or cosmetic field, brown kraft paper stickers will suit you best.

If looking for medical or pharmaceuticals then you should go for a synthetic one.

If you are in search to tag event memorials then mirror Korte gloss stickers would be recommended.

Thanks for Reading!

FAQs

Q: How to adjust the size of the sticker materials?

A: For this, you have to use die-cut stickers so that you can cut according to your desired size.

Q: Which sticker material is writeable?

A: Kraft paper stickers are the ones you can easily write it on.

Q: Which sticker material is used for fire extinguishers or any other fireplace?

A: Self-adhesive vinyl stickers are best suited for such cases as this material does not catch fire.

I am Mason, a Team Leader & Writer, a proactive and collaborative individual who works closely with my team to achieve shared goals. I am skilled in managing projects and am able to lead my team to success by setting clear expectations, providing guidance and feedback, and fostering a positive and productive work environment. I have a deep understanding of printers, sticker printers, label makers, sublimation, and craft markets, and use my knowledge to produce high-quality content that is both informative and trusted for the readers.