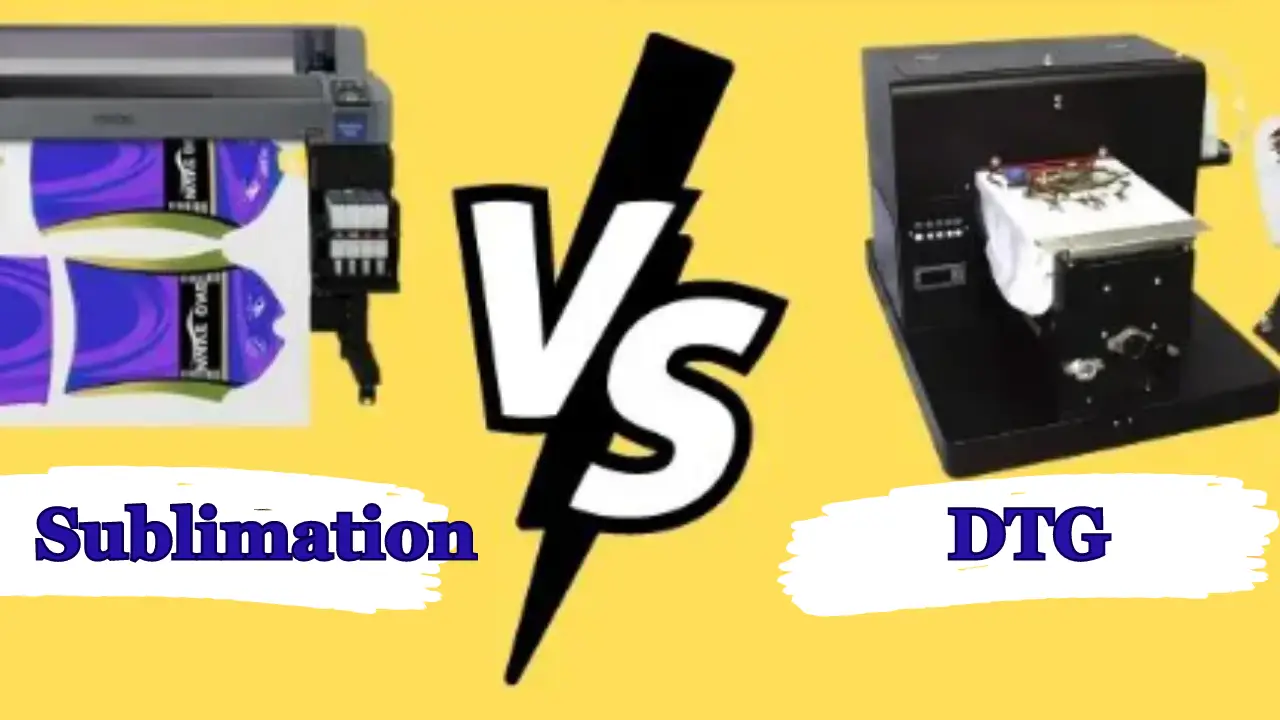

Sublimation VS DTG Printing Differences and How They Work

Several advanced print technologies have come to the surface, when it comes to textile printing. You can print artwork, images, patterns, or text onto fabric and customize it however you like. The evolution of print technologies has paved the way for crafty individuals to show their creativity and engrave designs on objects like t-shirts, caps, mugs, shoes, and more. Sublimation and direct-to-garment are two such print techniques known majorly for quality results, reliability, and user-friendliness.

If you are planning on starting a customization business, the abundance of fabric printing methods may overwhelm you and make it hard to understand which suits your apparel business best. The article will compare the two most popular digital printing technologies and highlight their advantages and disadvantages to help you make an informed choice.

Sublimation Vs DTG

| Particulars | Sublimation | DTG |

|---|---|---|

| Sublimation VS DTG Print Quality | Excellent color accuracy and vibrancy. High-resolution prints. You cannot print white ink through sublimation printing. Therefore, you can only print designs onto white or light-colored substrates. |

Photorealistic designs. DTG printing can print white inks so you can engrave your designs onto dark-colored garments. The vibrancy and impression of the designs are top-notch if you pre-treat the garment well. |

| Sublimation VS DTG Media Compatibility | You can only print on polyester-coated materials. The chemical reaction for sublimation printing would only allow the design to adhere to polyester-coated surfaces. But you can transfer your designs onto various substrates like caps, hoodies, ceramic mugs, phone cases, flip flops, etc. The designs become a part of the fabric as the inks pierce themselves into the material. Images look immersive and are highly durable. The prints will last as long as the fabric itself. |

You can print on a wide range of fabrics, such as cotton, polyester, cotton-poly blends, denim, wool, linen, canvas, etc. Pretreatment is mandatory to ensure the design looks vibrant no matter which fabric or color you choose. You can only print on flat surfaces, not on caps, etc. Also, you cannot print on hard surfaces like a ceramic mug. |

| Sublimation VS DTG Durability | The designs become a part of the fabric as the inks pierce themselves into the material. Images look immersive and are highly durable. The prints will last as long as the fabric itself. | DTG-printed designs are durable; they survive fifty to sixty washes. However, the durability is not comparable to sublimation printing. A DTG printer sprays the ink on the fabric, and then you have to cure the design using heat, unlike dye-sublimation, where the inks are infused into the fabric permanently. |

| Sublimation VS DTG Print Speed | Sublimation printing is suitable for one-offs and small-batch orders. It requires printing the design on transfer paper and then pressing it onto the fabric with a heat press. The process requires more manual labor and attention than DTG printing. The print speed is not comparable to DTG printing which is faster. | DTG print process is quick and hassle-free. It allows you to finish high-volume print jobs smoothly. The easy-to-use control panel makes switching between the designs faster and easier for print-on-demand jobs. You can print on white t-shirts in thirty seconds and more complex patterns on dark fabrics in a couple of minutes. |

| Sublimation VS DTG Cost | The initial investment for sublimation printing starts from a few hundred dollars. You can get a quality sublimation printer within a thousand dollars and a heat press for $500-600. | The upfront investment for DTG printing is significantly higher than for sublimation printing. DTG printers are expensive; you can go as high as $25,000 if you have the budget. Then there is the cost for a heat press and pretreatment machine, for which you will need a few thousand dollars. |

| Sublimation VS DTG Equipment | For sublimation printing, you need a sublimation printer and a heat press. | For DTG printing, you need a DTG printer, a heat press, and a pretreatment machine. |

Let’s learn about dye-sublimation and direct-to-garment print processes.

What is Sublimation Printing?

The sublimation print technique involves transferring a design onto a material using heat. You need to print the design on transfer paper and then infuse it onto fabric or other materials with a heat press. Sublimation printing is well-known for high-quality, durable prints. You can print graphics and images on synthetic fabrics with a high polyester or polymer content. A sublimation printer can also print on ceramics, metal, glass, and numerous other materials.

How Does Sublimation Printing Work?

A sublimation printer utilizes inkjet printing technology and sublimation dyes. It produces a mirror image of the design on specialty sublimation paper. Then, you affix the design onto your sublimation blank by applying heat and pressure. It is a chemical print technique that converts the solid inks into gases and then back to a solid state using heat.

The inks penetrate into the substrate; hence the results are permanent and do not fade, peel or crack. A sublimation printer uses four to eight ink cartridges and gives excellent photographic reproduction. It is a quick, convenient, and clean process, which makes it favorable among customization business owners.

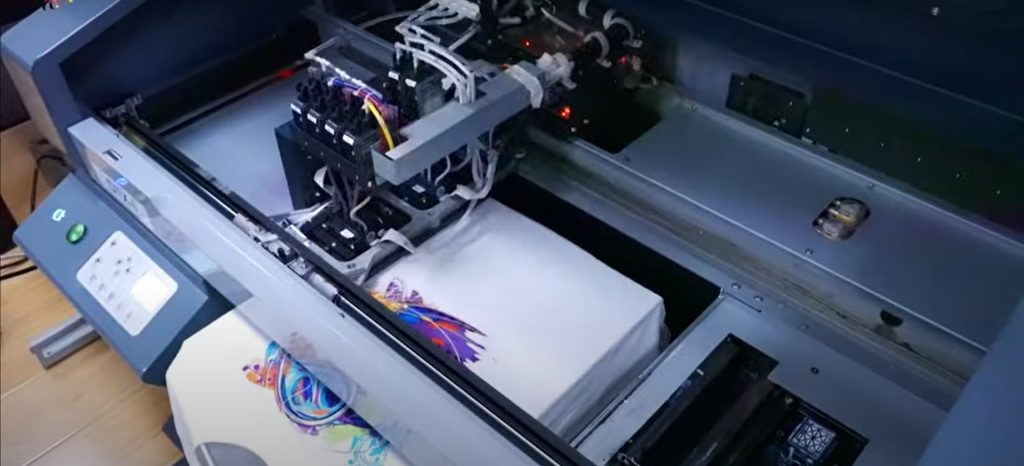

What is DTG Printing?

With DTG printing, you can print the designs directly onto fabric using a specialized DTG printer. It allows you to create high-resolution, detailed images on different fabric materials in different colors. A DTG printer works like an inkjet printer and uses water-based inks that the garment absorbs instantly so the design won’t smudge.

The images you print through DTG printing will be long-lasting and survive multiple washes. A DTG printer uses four inks to produce a wide range of color combinations and tones. It is a budget-friendly choice suitable for short-run prints.

How Does DTG Printing Work?

Direct-to-garment print process is quick and easy. All you need to do is pre-treat the fabric and then feed it to the printer so it can print your custom design onto it. Pretreatment helps blend the design with the material of your substrate. It requires a hand sprayer or an automatic pretreatment device.

A DTG printer uses inkjet print technology that sprays the ink onto a cloth, just like a sheet of print paper. After that, you cure the image with a heat press or a garment dryer. Unlike sublimation printing, you can print on cotton and numerous other garments. The designs will be immersive and look like a part of the fabric.

Pros and Cons of Sublimation Printing

Pros

- Prints on hard surfaces.

- The process is easy to learn.

- Low initial investment.

- Sublimation printers have a small footprint.

- High-quality, durable prints.

- No pretreatment is required.

Cons

- Cannot print on dark colors.

- Does not print on cotton.

Pros and Cons of DTG Printing

Pros

- Prints swiftly and requires less effort.

- Suitable for mass production.

- Excellent print resolution.

- Low per print cost.

- Allows you to print large images and designs. Maximum print size is 16” x 20”.

- Print on natural fabrics like cotton, linen, etc.

- Produces excellent custom designs on dark colors.

- Uses eco-friendly inks.

Cons

- High upfront cost.

- Pre-treatment required.

- Occupies a lot of space.

- You can only customize objects with flat surfaces. It does not print on ceramics or other hard surfaces.

- Print durability is lower than sublimation prints.

Which Printing Method is the Best?

Both these print technologies are excellent in terms of print quality, speed, durability, and ease of use. Which method suits you best depends on your unique business goals, budget and space constraints, and the specific type of apparel decoration projects. These print techniques have different applications. For instance, sublimation printing is a perfect fit if you often need to print on hard surfaces like caps, mugs, etc.

But if your customization projects involve printing on different fabric types in light and dark colors, and you have a high print volume, DTG printing is more suitable and practical. The initial investment is another decisive factor. You can start a sublimation printing business in less than $15,000, but the upfront cost for DTG printing may go as high as $40,000. So choose wisely!

Both sublimation and DTG print techniques can elevate your customization business; you can choose either or both in parallel. If you think you have the budget and space to accommodate the equipment for both methods, keeping them both and trying out different customization projects can be incredible. You can be as versatile and creative as you want but remember to prioritize quality, customer satisfaction, and ROI while at it!

Final Thoughts

Designing and printing images, text, logos, and attractive patterns on apparel can be fun. You can customize t-shirts, towels, cushions, jackets, laptop cases, ceramics, jigsaws, and many other objects. With time you can get better at designing and printing quality images and start making extra cash by selling customized goods. Once you decide to go into the customization business, think about what type of printing process is best for you. We hope the article will help you pick the fitting print technique for your print quantity, material, budget, and other business specifics.

I am Zamal Fatima, a skilled and experienced writer having a passion for technology, gadgets, printers, crafting, and DIY. As a technology expert, I have a deep understanding of the latest advancements in gadgets and devices and am able to produce insightful and informative articles that provide valuable insights into the world of technology. Always striving to improve my skills and knowledge.