How Does a Thermal Printer Work? Components and Process

Thermal printers are efficient, reasonably-priced printers perfect for producing shipping or product labels, receipts, bar codes, etc. If, you want a low-budget, reliable machine that can print highly legible, long-lasting labels in a few seconds, a thermal printer is your best choice. You can choose from different thermal printers like mobile, desktop, and industrial-grade thermal printers; there is one for everyone.

The thermal printing process is entirely different from laser or inkjet printers. Thermal printers do not require ink or toner; they utilize a heated print head. It presses against print media to generate text or images. If you want to know how does a thermal printer work, the article is for you. It contains all the information about thermal printing process along with the applications and advantages of thermal printers.

What is a Thermal Printer?

A thermal printer is an easy-to-use printer that uses heat to print labels eliminating the need for toner or ink cartridges. It saves you the hassle of replacing and refilling the inks from time to time. They are compact; you do not need a huge space to store them. The labels they produce are smear-proof, legible, and durable. A thermal printer is perfect for small businesses as it is handy, quick, energy-efficient, reliable, and affordable. Let’s learn how a thermal printer operates in detail.

Thermal Printing Process

Basic Components

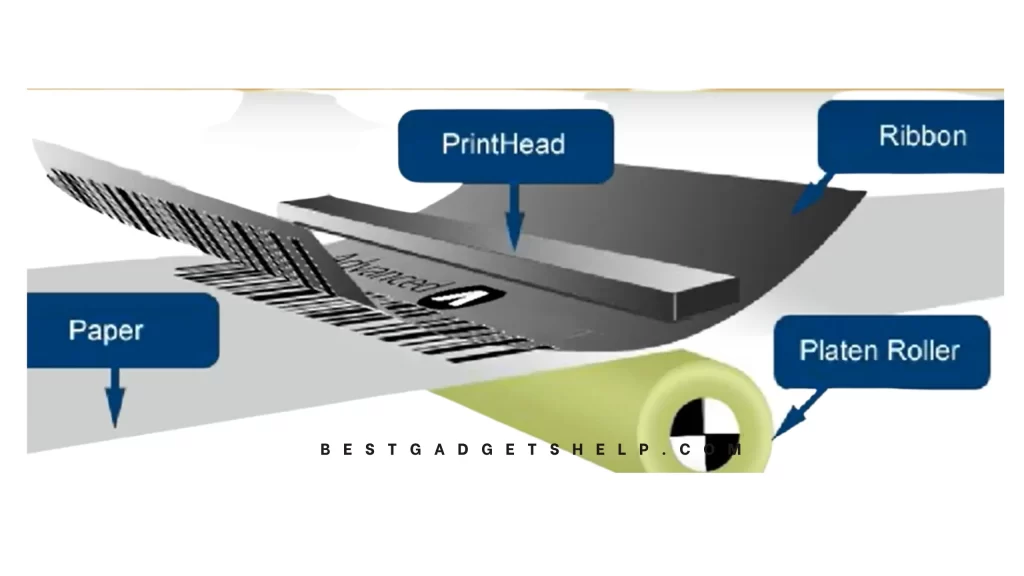

The three significant components of a thermal printer are a heated print head, a platen, and a spring. The platen is a rubbery cylindrical roller through which you can feed your print media. Then there is the print head that produces heat when it receives an electric current. Finally, the spring; it effectively applies pressure so that the print head can transfer heat to the paper.

The print head has a matrix of pins that act as resistors; when the printer gets a print command, it passes a current through the energizing resistors causing them to heat the print head. Platen moves the print paper underneath the print head when it is heated. This final step involves the print head reaching its operating temperature. The spring then presses it against the wax-based thermal paper. The heat applies to the areas where it wants the print and turns the wax-based ink black. Once it cools down, the text or pattern becomes permanent.

Thermal printing has two print technologies; direct thermal and thermal transfer. The core printing method is the same, but the print for both is different, and how they transfer heat is slightly different. Let’s dive deep into the two thermal printing technologies.

Direct Thermal Print Technique

The direct thermal printing method uses chemically treated thermochromic paper that darkens when a heated print head touches it. A direct thermal printer does not require ink, toner, or ribbon to produce prints and relies solely on heat. Thermal paper has a heat-sensitive coating; the print head applies heat and pressure to print text and graphics. The print head targets the specific areas of the thermal paper where it needs the print. As the print media rolls through the printer, targeted areas receive heat and turn darker. The paper and print head come in direct contact during the direct thermal print process.

Direct Thermal printing is the most popular copying technique with many Point-of-Sale printing companies. Although more popular, there is one drawback to direct thermal printing method. The labels it produces are not as durable as thermal transfer labels. Thermochromic paper is sensitive to heat and light; excessive exposure to these two can make the print on the labels fade away.

Also, direct thermal printers can only print in one color; which may limit your options. However, one thermal paper type allows printing in different colors- magenta, cyan, and yellow. All these colors react at different temperatures, and a combination of temperature control and heat pulse lengths helps generate a range of colors on the paper.

Direct thermal labels are suitable for businesses where the product has minimal exposure to heat and moisture. Direct thermal printing is excellent for short-term print jobs like receipts, warning signs, etc. This type of thermal printer is cheap, easy to operate, and cost-effective as it does not require ink. They are also easier to clean and maintain. There are many label applications where labels only need to be visible for a few months; direct thermal printers can be excellent for such businesses.

Thermal Transfer Print Technique

Thermal transfer print technique uses a heat-sensitive ribbon and a thermal print head. It is a thin film made up of wax or resin, or a combination of both, and contains a dye-based ink. A thermal transfer print head has tiny pins that a microprocessor controls. The processor determines which pins it needs to heat to create a particular pattern or image. The heated print head melts the ink and presses it onto the paper during the thermal transfer.

The paper absorbs the ink permanently, resulting in high quality images, legible text, and long-lasting labels. The print head and print media do not come in direct contact during the thermal transfer print technique; thermal ribbon acts as an intermediary between them.

Thermal transfer printers are compatible with various print media, such as polyester, polypropylene, paper, etc. Unlike direct thermal printers, you can print in more than one color by using multiple ribbons in different colors. Also, the labels you make with thermal transfer printers are durable and do not fade over time.

Thermal transfer printers are also reasonably priced, but replacing ribbons every so often increases operational costs. For businesses needing durable, smear-proof labels, and highly legible text for receipts, tickets, name tags, etc., a thermal transfer printer is a suitable choice.

However, you need to consider the material of the thermal ribbon. Wax-based ribbons produce long-lasting labels, but are sensitive to moisture, oils, and chemicals. Wax-resin and resin-only ribbons are water-resistant, more durable, and deliver precise images and easily scannable text. These labels offer superior protection against heat, light, chemicals, oils, and abrasives.

You can use resin-only ribbon with polyester, vinyl, polypropylene, and similar materials. The choice of print media and thermal ribbon boils down to the type of your business and your distinctive labeling requirements. Thermal transfer labels are excellent for automotive, aerospace, engineering, and marine industries.

Who needs a Thermal Printer?

Thermal printers have several applications. We have compiled a list of some of the most prominent businesses that could use a thermal printer. Let’s look at them:

- Health care and medicine

- Transportation

- Shipping industry

- Logistics

- Inventory management

- Barcodes

- Hospitality

- Retail

- Event planning

- Sports and recreational activities

- Government

- Manufacturing

You can also get a thermal printer for personal use. Many reputable brands offer portable thermal printers that consumers use to make sticky notes, pantry labels, shopping lists, color images, puzzles, and more.

Thermal Printer Advantages

There are numerous advantages to owning a thermal printer. Here are a few of them:

- Thermal printers are affordable, energy-efficient, and cost-effective.

- They are compact and portable.

- Some thermal printers allow mobile printing making it easier to create labels at home.

- They are easy to use and fast.

- Thermal printers can produce water-resistant, fade-proof, high-quality labels and tags.

- Less prone to operational errors and malfunctions, and easy to maintain.

- A reliable, good-quality thermal printer can last as long as ten years.

- Compatible with a wide range of materials and serves several applications.

Final Words

Thermal printers are good-quality, sustainable machines appropriate for printing barcodes, shipping and product labels, wristband tags, receipts, and other similar items. They cannot provide the quality, flexibility, and versatility of inkjet or laser printers but can fulfill your label printing needs smoothly and efficiently at less than half the price.

Small businesses with budget and space constraints can benefit from thermal printers considerably. They produce long-lasting, high-quality labels, and the operative costs are significantly lower than other printers. We hope that the article was helpful for you and you got the answers to your queries about thermal printing.

FAQs

Q: Can I use any paper with a thermal printer?

A: No, you can only use a specialized thermal paper capable of changing color when it receives heat.

Q: Can I print stickers with a thermal printer?

A: Yes, as long as you use thicker sticker paper that can withstand the heat a thermal printer generates.

Q: Can I print labels in color using a thermal printer?

A: Yes, but you will need special thermal paper and a thermal transfer printer.

Q: How long does a thermal printer last?

A: Thermal printers are sturdy and reliable. They can survive in harsh weather conditions. With appropriate care and maintenance, you can keep them operational for a long time.

I am Zamal Fatima, a skilled and experienced writer having a passion for technology, gadgets, printers, crafting, and DIY. As a technology expert, I have a deep understanding of the latest advancements in gadgets and devices and am able to produce insightful and informative articles that provide valuable insights into the world of technology. Always striving to improve my skills and knowledge.