3 Ways To Make Stickers at Home in 2023 I Vinyl Stickers

“His gaze glossed over a stack of wooden crates and landed on a steamer trunk that was covered with stickers from all over the world.”

― Megan Frazer Blakemore, The Water Castle

A quote from THE WATER CASTLE says it all.

Stickers are an amusing way of adding a taste of fun and entertainment to your essentials at a low cost. Have you ever barged into the shop intact with fun stationery, art supplies, journalling essentials, and much more? Who else didn’t fond of collecting stickers in their childhood? Yes of course we all do. all of us had the devotion to decorating our rooms, dressing mirrors, laptops, mobile back covers, books, and autographed diaries. with cute stickers. Okay not everyone decorates their autographed diaries but this is me and I hope you get the idea.

If you are a student but thinking to give a kick start to your career by setting up a small business of printing or making stickers on your own at home. So, you have to worry not and go ahead a few minutes read of 3 ways to make stickers at home.

What you all need is:

- Laptop with MS Office or any relevant software through which you can design your stickers.

- An inkjet printer

- Sticker paper. (To get to know about sticker materials read also what materials are used to make stickers)

- Scissors or cutters for cutting stickers

Now you are all set to make stickers.

3 STEPS TO BEING A CUSTOM STICKER MAKER AT HOME

There are many ways to make or print stickers at home but this depends upon the desired quality and detailing in the sticker. Designing on your own can save a lot of money and give you expertise as you can easily test new ideas.

You are just 3 steps away to design your sticker.

So, let’s get started.

1. Design Your Sticker First

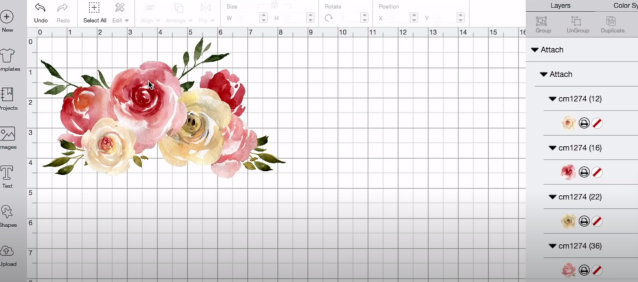

There are several different ways to turn your idea or imagination into amazing art and this can be done with the help of many software. if you are an artist of entry-level then Microsoft paint is the best option to go with your creativity. But if you are good at playing with tools then give a chance to adobe photoshop and illustrator a. Furthermore, if you are an intermediate artist with little knowledge of designing then go explore the most trending CANVA.

CANVA helps artists from beginner levels to the pro level. it has a vast variety of templates whatever you want to design. You can either go by sketching it on your apple I-pad if you are having it.

To Do List:

2. Devising And Arrangements

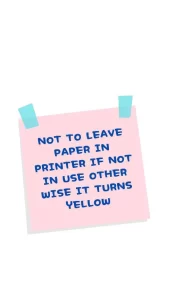

All set to go for a major step is planning and preparation of the printer to make everything crystal clear before moving towards the next step. A conventional inkjet printer is efficient in printing stickers.

But you have to go through the brochette that comes with the printer for a proper guideline about which sticker material could it print.

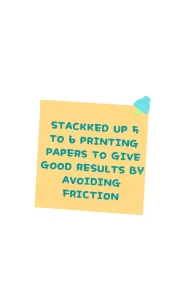

For this groundwork is needed and you have to see the customer reviews about that printer and ease your way. The printer setting may fluctuate according to the texture of surfaces, labels are the better option instead. While the layout must stand on the number of stickers to be printed per sheet and the size of the sheet. Start accommodating the page dimension by using MS WORD to fix more stickers on each sheet. Don’t forget to leave a gap after each sticker because this leads to easy cutting of stickers.

For a simple design, keep the following supplies with you:

- Right sticker or label paper

- A printer with sufficient dye and must be material friendly

- Laminating sheets or acrylic spray to safeguard the quality.

- Sticker packets if you are willing to make packs.

If you are printing stickers just for the sake of little enjoyment then any type of paper can be used, but if you are a professional designer and works with superior quality then vinyl stickers will be suited best for this case. Prioritize to check whether your printer supports vinyl material or not.

3. Final Printing and Disposal

In case you are customizing stickers on either a small scale or a large scale, the thing that only matters is the quality of the final product. Dull results have been obtained by poor-quality paper and thus cause bruises to certain object surfaces and this is possible where there is a lack of research.

If you are a beginner, so just print a sheet as the first trial to avoid major losses.

Go over with a fine tooth comb to visualize the quality before printing more sheets. review the color sharpness. Applying laminating sheets gives a barrier against water, making it water resistant. The acrylic spray did the same job by adding gloss to the sticker.

The final step is cutting the stickers to the desired shape with scissors or cutters.

How to Make Vinyl Stickers at Home

Vinyl stickers are adhesive-backed stickers made from vinyl. vinyl stickers can be printed on a home printer and are durable enough to withstand wind, rain and sunlight. vinyl stickers are popular for use as bumper stickers, window decals and other applications where durability is important.

To print vinyl stickers at home, you will need the following supplies: vinyl sticker paper, a computer with a printer, scissors or a die cutter, and an adhesive such as a spray mount or contact cement.

Vinyl stickers are most commonly sold in the market with diversity in their usage from laptops, notebooks, bumper-stickers, glass stickers, water bottles, promotional labels, and many more. The processing steps of making vinyl sticker is simple and similar to that of ordinary paper stickers. The addition of lamination coating or any acrylic spray may give gloss to the final look of a sticker. They are quite easier to make. A few tools, an inkjet printer, and a pinch of creativity are the only things you need.

These simple steps are divided into 2 parts:

1st Part (Sketching and Printing)

- Building up your ideas into drawings and print and make sure to fix your design on an 8 x 11-inch (20.3 x 27.9 cm) piece of paper.

- Designing on a computer (using adobe photoshop or illustrator) is the best option, set your resolution to 300 pixels per inch to print a pleasant picture.

- After finalizing your design save it in png format. To print various designs on one sheet, paste the design in rows.

- Print your sticker by installing vinyl paper in the printer, and set HD quality print settings in your editing software. Glossy vinyl sticker paper may give an extra glaze.

2nd Part (Laminating and Cutting)

- Executing laminate sheets to your stickers is the way to make them protective against water and UV.

- Peel off the back, line the top edge, press using fingertips, and this sticks on the sticker.

- Air bubbles are avoided by pressing the sheet with some sort of ruler or credit cards may also be used.

- Next step is cutting the stickers with scissors or a cutter.

- Now remove the backing and apply the sticker where ever you want. Dry the area before applying stickers.

Important Tips while Printing Vinyl Stickers At Home

- Make sure the vinyl sticker paper you are using is compatible with your printer.

- The vinyl sticker paper should be slightly bigger than the image or text you want to print on it.

- Use high-quality vinyl sticker paper for best results.

- Follow the printer’s instructions carefully for printing vinyl stickers.

- If you are not happy with the results, try again with a different vinyl sticker paper.

Now that you know how to make & print vinyl stickers at home, it’s time to get creative!

You can use vinyl stickers for a variety of purposes, such as:

- Labeling your belongings

- Decorating your notebooks or textbooks

- Making invitations or announcements

- Adding text or images to your clothing

- And much more!

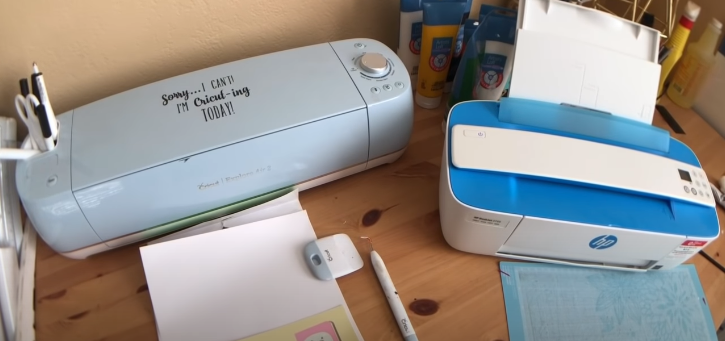

List of Best Vinyl Cutters for Home Use

1. Cricut Explore Air

2. Silhouette Cameo 4

3. Brother ScanNCut

How to Make Paper Stickers at Home

If you are great at designing and sketching, why not turn this skill in a way that gives you earnings?

Sticker papers are produced with first-class paper material, these are the simplest yet pocket-friendly thing that happens to students who are willing to begin their sticker-making journey as a side business. Available in various sizes, shapes, and designs and applicable as name tags, labels, decorating diaries, and much more.

The sticker-making process goes through 3 steps also discussed before

- Designing

- Printing

- Cutting into shapes.

the most important is to remember the keys discussed below before you start making paper stickers.

Wrap up

Many people think sticker-making is the most pressuring work, Yes, it is true, I am not denying but once you become a native custom sticker maker you start spending most of your leisure time designing and trying newer creations and this gives you a way out from annoyance and great money saver. After reading the blog I am pretty sure, becoming a sticker maker is no more a difficult task.

There are many other competitors in the market that sell unique durable and best-quality stickers at wholesale prices which are budget friendly for the end users. So just to meet their level invest most of your leisure time in doing sticker sketches.

FAQs

Q: What types of vinyl stickers can be printed using vinyl sticker printers?

You can print vinyl stickers in any shape or size you want. However, most vinyl sticker printers are limited to printing within a certain range of sizes. Be sure to check the printer’s specifications before purchasing it.

Q: How do I print vinyl stickers at home?

Printing vinyl stickers at home is a very easy process. All you need are a vinyl sticker printer, vinyl stickers sheets, and an inkjet or laser printer.

Q: Can I print vinyl stickers using my color inkjet printer?

Yes, you can print vinyl stickers using your color inkjet printer.

Q: What is the difference between vinyl sticker printers and vinyl cutter?

Vinyl sticker printers are devices that print vinyl stickers using an inkjet or laser printer. Vinyl cutters are devices that use a sharp blade to cut vinyl stickers into any shape or size you want.

Q: Can I print vinyl stickers using a color laser printer?

Yes, you can print vinyl stickers using a color laser printer.

Q: What type of vinyl sticker paper should I use when printing vinyl stickers at home?

There are two types of vinyl sticker paper you can use when printing vinyl stickers at home – glossy and matte. Glossy vinyl sticker paper produces high-quality stickers with a shiny finish, while matte vinyl sticker paper produces stickers with a dull finish.

Q: What is the best way to cut vinyl stickers using a vinyl cutter?

The best way to cut vinyl stickers using a vinyl cutter is by using the “vinyl print and cut” setting. This setting will allow you to print your vinyl stickers and then automatically cut them into the desired shape or size.

Q: What are decals?

Decals are printed in a larger format than stickers and are designed to use outdoors with a long-lasting adherent.

I am Mason, a Team Leader & Writer, a proactive and collaborative individual who works closely with my team to achieve shared goals. I am skilled in managing projects and am able to lead my team to success by setting clear expectations, providing guidance and feedback, and fostering a positive and productive work environment. I have a deep understanding of printers, sticker printers, label makers, sublimation, and craft markets, and use my knowledge to produce high-quality content that is both informative and trusted for the readers.