What is DTG Printing? A Comprehensive Guide in 2023

What is DTG printing? DTG printing, or Direct to Garment printing, is a process that allows you to print custom designs onto t-shirts and other garments. This process has gained in popularity in recent years, as the quality of DTG prints has continued to improve. In this guide, we will discuss what DTG printing is, how it works, and DTG printing pros and cons. We will also compare DTG printing to screen printing and sublimation printing.

DTG printing works by using special inkjet printers to print designs directly onto garments. The advantage of DTG printing is that it allows for very detailed and complex designs to be printed onto t-shirts and other garments. DTG prints also tend to be very soft and comfortable, as the ink is absorbed into the fabric of the garment.

Before DTG printing became popular, screen printing was the most common method of printing designs onto garments. Screen printing is a much older technology, and it works by using a stencil to apply ink onto a garment. Screen printing is generally more expensive than DTG printing, and it requires a higher level of skill to produce high-quality prints.

With DTG printers you get over 16 million colors to your shirt in a single pass.

In the 1990s, Matthew Rhome invented what is now DTG printing while working on his Ph.D. at Rutgers University.

The first patent for DTG printing was filed in 1999, and the technology has continued to evolve since then. Today, there are a number of different DTG printers on the market, from entry-level machines to high-end industrial printers.

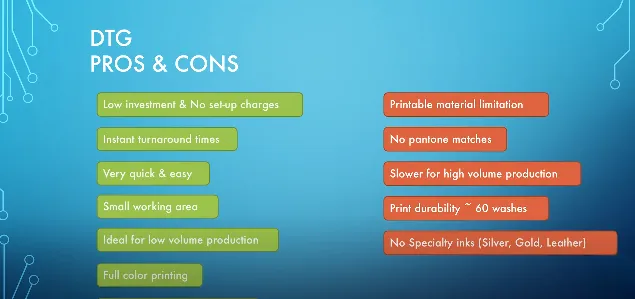

Pros and Cons of DTG Printing

Advantages:

- Detailed Designs

- Full Spectrum of Colors

- Easy to use and Simpler

- Cut off Labour and Training

- Quick Turnaround

- Fit in Smaller Space

- Environment Friendly

- Lower Cost Per Unit

Detailed Designs

One of the main advantages of DTG printing is that it allows you to print very detailed designs.

This is because the inkjet heads on DTG printers are very small, and they can print designs with a high level of detail. On contrary, screen printing is limited by the size of the stencils that are used.

This means that screen printing is not well suited for printing very detailed designs. Clothing industries that require highly detailed and unique designs, such as sportswear or luxury brands, often prefer DTG printing. You will not spend your money and time to get the designs that lack in detail? will You? There is a lot of competition in the market, so a detailed design will make you outrank your competitors.

Full Spectrum of Colors

Another advantage of DTG printing is that it allows you to print a full spectrum of colors. In garment printing, the colors are very important, as they can make or break your designs. With DTG printing, you have access to over 16 million different colors. This means that you can print very complex designs with a wide range of colors.

Some industries are affiliated with specific promises to deliver like school uniforms or fitness clubs and gym. Their apparel are containing their logos and other information like names which are required to be in a specific color. So, with DTG printing, you can easily get your design in the required colors plus you have a good opportunity to expand your business through the advertisement via logos.

Easy to Use and Simpler

DTG printing is very easy to use, as it does not require any special training or skills. This is because the printers are designed to be used by people with little to no experience in garment printing. All you need to do is load your design into the printer and hit print! This is in contrast to screen printing, which requires a significant amount of skill and experience to produce high-quality prints.

Remember: With great power comes great responsibility! You need to be careful while using DTG printers as a slight mistake can result in the wastage of ink and time. You can try almost everything but don’t go too broad with the designs in the beginning.

Cut off Labour and Training

As DTG printing is very easy to use, it does not require any special training or skills. You do not need to invest in hiring or training staff to operate the printers. All you need is someone who can load the design into the printer and hit print! This can save you a lot of money, as you do not need to invest in training staff. While the screen printing process is a bit complicated, it does require some experience and skill to produce high-quality prints.

Quick Turnaround

DTG printing has a very quick turnaround time. This is because the printers are designed to print small batches of garments quickly. In contrast, screen printing is a much slower process, as each garment needs to be individually set up for printing. This can make screen printing very time-consuming, particularly for small businesses or when you need to print a large number of garments.

Note: Quick turnaround times can be a win-win for you and your team. The quicker we create products, the more orders that will result in increased productivity rates too!

Fit in Smaller Space

DTG printers are very compact and can be easily stored in a small space. This is in contrast to screen printing, which requires a large amount of space to set up the equipment. This can be a major advantage for small businesses or those who do not have a lot of space to work with.

Fact: DTG printers have weight ranges from 40-180lbs (18-82kg) and screen printing set-ups can weigh upwards of 600lbs (272kg).

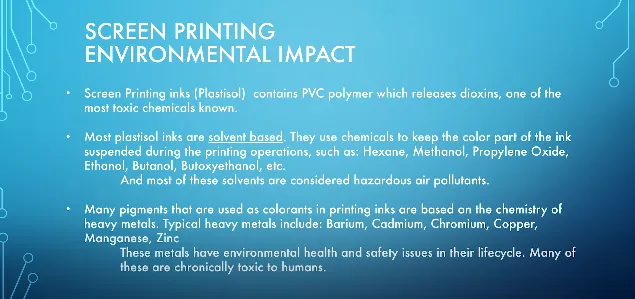

Environment Friendly

Environment friendliness is the new trend. People are now more aware of the importance of saving our planet. So, if you want to join this environment-friendly bandwagon, then DTG printing is the best option for you. This printing process does not require any chemicals or other harmful substances. In contrast, screen printing uses a variety of chemicals, which can be harmful to the environment.

Fact: Industries are polluting the environment in many ways. The textile industry is no different! It is one of the leading industries which are polluting our planet. Their contribution to water pollution is about 20%.

Lower Cost Per Print

DTG printing has a lower cost per print than screen printing. This is because the ink and garment costs are much lower with DTG printing. In addition, there is no need to purchase screens or set up the equipment, which can save you a significant amount of money.

Note: The lower cost per print can be a major advantage for businesses who are looking to save money on their garment printing.

Flexible Design

Unlike screen printing, DTG printing does not require a minimum order quantity. This means that you can print just one garment if you need to. This is a major advantage for businesses who need to print small batches of garments or who need to print on a variety of garment types.

DTG has the potential for you to expand into new markets and genres of clothing. From novelty fashion dresses to everyday wear, t-shirts, jeans, and more – DTG can provide you with the ability to be more flexible with the types of garments you produce.

What to Look For While Going With DTG Printers

There are a few things to keep in mind when choosing a DTG printer. First, you need to decide what type of garments you want to print on. T-shirts are the most popular choice for DTG printing, but you can also print on hoodies, tank tops, and other types of clothing. Second, you need to consider the quality of the prints you want to produce.

DTG printers range in price from a few thousand dollars to over $100,000, so you need to decide how much you are willing to spend on a machine. Finally, you need to think about the types of designs you want to print. DTG printing is best suited for small-scale production runs and complex designs. If you want to print large quantities of t-shirts with simple designs, screen printing may be a better option for you. You can go with the heat transfer also.

Learn About: 10 Best Heat Press For Sublimation

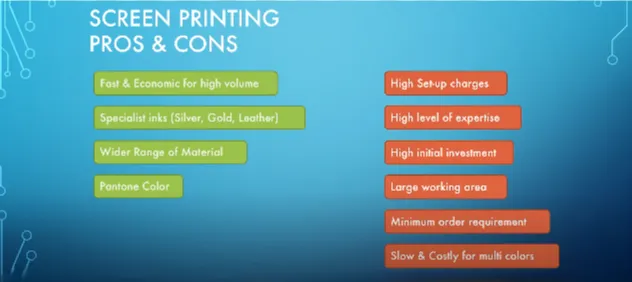

What is the Difference Between DTG Printing VS Screen Printing?

The two most popular methods for printing onto garments are DTG printing and screen printing. So, what is the difference between these two methods?

DTG printing, or Direct to Garment printing, is a process that uses inkjet technology to print designs onto t-shirts and other garments. This method is ideal for small runs of shirts, as there is no need to create a screen printing stencil. DTG prints are also known for their high quality, as the ink is absorbed into the fabric of the garment.

Screen printing, on the other hand, is a method that uses a stencil and ink to print designs onto garments. This method is ideal for large runs of shirts, as it is more cost-effective than DTG printing. Screen printing also has a bit of a vintage look, as the ink sits on top of the garment rather than being absorbed into the fabric.

So, which method is right for you? If you are looking for high-quality prints in small quantities, DTG printing is a great option. If you are looking for a more cost-effective option for large runs of shirts, screen printing is the way to go.

Important Note:

What is the Difference Between DTG Printing VS Sublimation Printing?

DTG, or Direct To garment printing is a process that allows you to get high-quality results with greater color mixing and photorealism as compared to traditional or screen printing. This type of printing is ideal for small runs of shirts.

Sublimation printing is a process that uses heat to transfer dye onto specially coated garments. This method is ideal for large runs of shirts, as it is more cost-effective than DTG printing. Sublimation prints are also known for their durability, as the dye is bonded to the fabric of the garment.

Read: Best Sublimation Printer for Beginners

The main drawback of DTG printing is that it is more expensive than other methods. The main disadvantage of sublimation printing is that it can only be done on certain types of fabrics (White Polyester).

How Does DTG (Direct-to-Garment Printing) Work?

The working of DTG printers is not very different from the way inkjet printers work. The only difference is that instead of paper, a garment is used as the printing surface. They use specialized heads that have multiple nozzles that spray the ink onto the garment. The ink used in DTG printing is water-based and gets absorbed into the fabric.

Check the DTG ink.

Direct-to-garment printing works best on natural fabrics such as cotton and linen. The ink is first pretreated onto the fabric and then the design is printed. After printing, the garment is cured so that the ink becomes permanent and does not wash off.

DTG printing has many benefits over traditional methods such as screen printing. The main advantages are that there is no need to create a separate stencil for each design and the print quality is very high. DTG printing is also much faster than screen printing and can print complex designs with multiple colors.

Final Words

We hope this guide has helped you understand What is DTG printing and how it works. If you are looking for high-quality garment printing, DTG printing is a great option. If you are looking for a more cost-effective option, screen printing may be a better choice. Going with DTG printing, screen printing or sublimation printing depends on the number of shirts you want to print and the design you are looking to put on them. Choose wisely!

Thanks for reading!

FAQs

Q: How long does DTG printing last?

A: it is heard that it lasts about 50 washes and however DTG printing is very durable and will last for the life of the garment.

Q: Is DTG printing good quality?

A: Yes, DTG printing is good quality. The ink is absorbed into the fabric of the garment which results in a high-quality print.

Q: Can I print any design with DTG printing?

A: Yes, you can print any design with DTG printing. This printing method is great for complex designs with multiple colors.

Q: I am a beginner. Can I use DTG printer?

A: Yes, anyone can use DTG printers. They are easy to operate and the learning curve is not very steep.

Q: What are the pros and cons of DTG printing?

A: Pros: high-quality prints, fast printing, no need for separate stencils, can print complex designs and Excellent output for small batches.

Cons: more expensive than other methods. Not suitable for larger volumes.

I am Mason, a Team Leader & Writer, a proactive and collaborative individual who works closely with my team to achieve shared goals. I am skilled in managing projects and am able to lead my team to success by setting clear expectations, providing guidance and feedback, and fostering a positive and productive work environment. I have a deep understanding of printers, sticker printers, label makers, sublimation, and craft markets, and use my knowledge to produce high-quality content that is both informative and trusted for the readers.