What is Reverse Printing? Which is Best Traditional or Reverse Printing 2023

When it comes to printing, there are two main types: Traditional and Reverse. With traditional printing, the text or image is printed on the front of the paper. With reverse printing, the text or image is printed on the back of the paper. This can be a great way to add a unique touch to your projects! On this page, we will explore traditional vs reverse printing, reverse sticker printing, ink used for reverse printing and some of the best ways to use reverse printing in your work.

Traditional Printing

Traditional printing is a printing process where the inked image is transferred from a plate to a rubber blanket, and then to the printing surface. This type of printing is commonly used for large format printing, such as posters or billboards. Among all types of printing, the traditional printing process is the most common, and its share in the printing industry is currently estimated to be over 60%.

Reverse Printing

The reverse printing method is a great way to make the packaging for any product. This process of creating prints on inner boxes, wrappers or cans helps provide protection and gives it an attractive finish at once! The ink used in this technique does not come into contact with human skin which means that you can avoid dangerous chemicals. The ink is placed between the materials (packaging) by a lamination process.

The lamination process is a method in which two or more materials are bonded together by heat and pressure. This process is often used to create laminated glass, which is two or more pieces of glass bonded together with an interlayer of plastic. The lamination process can also be used to bond metal, paper, and fabric.

Traditional Printing vs Reverse Printing

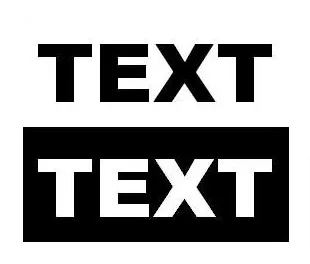

The main difference between traditional printing and reverse is the “Creation of Contrast” on paper. In traditional printing, the image areas receive ink while the surrounding paper does not get any ink. In reverse printing, images themselves don’t get ink but the paper areas around images get ink.

Which is Best Traditional or Reverse Printing?

Reverse sticker printing is also a great way to add a unique touch to your project. If you want your stickers or labels to stand out from the rest, then reverse printing is a great option for you. Reverse printing is a great way to add an extra layer of protection to your stickers or labels. If you are using them outdoors or in a place where they will be exposed to wear and tear, then reverse printing can help to prolong the life of your stickers or labels.

Which is Best Traditional or Reverse Printing? The answer to this question is not as simple as it may seem. If you are working on a project that requires stickers, then the answer may be different than if you are working on a project that requires labels or others. Here are some things to consider when making your decision:

- The type of project you are working on

- The quantity of stickers or labels you need

- The turnaround time you need the project completed

- The budget for the project

If you are working on a small project with a tight budget, then traditional printing may be the better option for you. However, if you are working on a large project with a longer turnaround time, then reverse printing may be the better option.

Ink Used for Reverse Printing

The viewer sees and is attracted by the brighter colors. Going with packaging materials, right and high-quality ink is very important. For the sticker, it is better to use lightfast inks that will not fade over time and exposure to sunlight. The company’s inks are so fine that they give the material a luxurious feel. The ink is absorbed in a way that colors make it easy on your eyes and confuse that nothing has been done with the material. Most customers choose these products because of their high-quality printing -and reverse-side printing only adds more high-definition colors to packaging products.

Read This: Flexo Reverse Printing Ink – China Factory, Suppliers, Manufacturers

A big responsibility lies at the end of manufacturers regarding the right use of ink and packaging. To ensure human health and safety, legislation have been made to counter the migration of chemicals to the products.

Best ways to use Reverse Printing

Here are some of the best ways to use reverse printing to enhance your projects:

- Reverse printing can be used to create unique and interesting patterns on your project surface.

- It can also be used to add an element of depth and dimension to your project.

- You can create a unique and striking border or edge on your project.

- Opt for it to highlight certain areas or elements of your project.

- Add an extra element of interest and intrigue to your projects with reverse printing.

Mostly Used for the printed packages for juices, snacks, biscuits, cans, ketchup.

How Does Reverse Printing Work?

Reverse printing is a printing technique where the image is printed on the back side of the substrate. This creates a unique effect, as the image appears to be floating on the surface. Reverse printing can be used on a variety of materials, including glass, metal, and plastic.

Reverse printing is often used for projects that require a high level of detail, such as photographs or artwork. The printing process allows for a sharper and more vibrant image. In addition, this type of printing is more durable than traditional printing, as it is less likely to fade or be damaged.

There are a few things to keep in mind when reverse printing. First, the image will be reversed on the back side of the substrate. This means that any text or numbers will appear backward on the finished product. Second, this printing can be more expensive than traditional printing, so it is important to factor this into your budget.

If you are looking for a unique way to enhance your projects, reverse printing may be the perfect solution. With its high level of detail and durability, this printing can help you create stunning results that will last for years to come.

FAQs

Q: Which gives better design traditional printing or reverse?

A: Traditional printing is better for simple designs, while reverse printing is better for detailed designs.

Q: What are the benefits of reverse printing?

A: The benefits of reverse printing include a sharper and more vibrant image, as well as increased durability.

Q: What are the things to keep in mind when reverse printing?

A: The image will be reversed on the back side of the substrate and text or numbers will appear backward. Additionally, reverse printing can be more expensive than traditional printing.

Q: How do I factor the cost of reverse printing into my budget?

A: When budgeting for a reverse printing project, be sure to factor in the increased cost of the printing process. Additionally, consider the number of materials you will need to purchase.

Q: I have a project that I think would be perfect for reverse printing. How do I get started?

A: To get started with a reverse printing project, if you are not confident to start your own, contact a local print shop or online printer. They will be able to provide you with a quote and help you get started with your project. if you have planned to start a packaging business then you need to hire a good packaging designer with reverse printing knowledge.

Q: what is the difference between surface printing and reverse printing?

A: In surface printing, the ink is applied to the top of the substrate, while in reverse printing, the ink is applied to the back of the substrate. This creates a unique effect, as the image appears to be floating on the surface.

Q: Can reverse printing be done at home?

A: While reverse printing can be done at home, it is often best to leave it to the professionals.

Feel free to ask questions if you have any.

Thanks for reading!

I am Mason, a Team Leader & Writer, a proactive and collaborative individual who works closely with my team to achieve shared goals. I am skilled in managing projects and am able to lead my team to success by setting clear expectations, providing guidance and feedback, and fostering a positive and productive work environment. I have a deep understanding of printers, sticker printers, label makers, sublimation, and craft markets, and use my knowledge to produce high-quality content that is both informative and trusted for the readers.